- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

Concepts for success are already created at the beginning of a project. We at Broetje-Automation combine profound knowledge and experience from more than 40 years in the fields of consulting, production and service. In the interaction of the upstream planning level in combination with German engineering skills, we offer our renowned customers a reliable partner in all aspects of consulting and engineering. An important step towards the factory of the future is the early recognition of potentials and their exploitation. Together we create added value that pays off.

Consulting

Successful project implementation begins with planning. As a technology-driven company, we support our customers as early as the development phase in order to develop efficient solutions for the factory of the future. Our core competencies lie in factory planning with simulation of production processes, evaluation of the efficiency increase of planned measures and comprehensive calculation of operating and investment costs.

Our employees draw on a wealth of experience in the planning and manufacture of plants and entire production lines. This creates valuable savings potential for our customers by minimizing risks in the planning phase, by increasing the efficiency of the production process and by calculating costs as accurately as possible. Together with our customers, we develop customized concepts that become reality and offer a modern approach to solving individual problems.

Engineering

For customized requirements, we offer expertise in different fields of engineering such as manufacturing engineering, commercial engineering and simultaneous engineering.

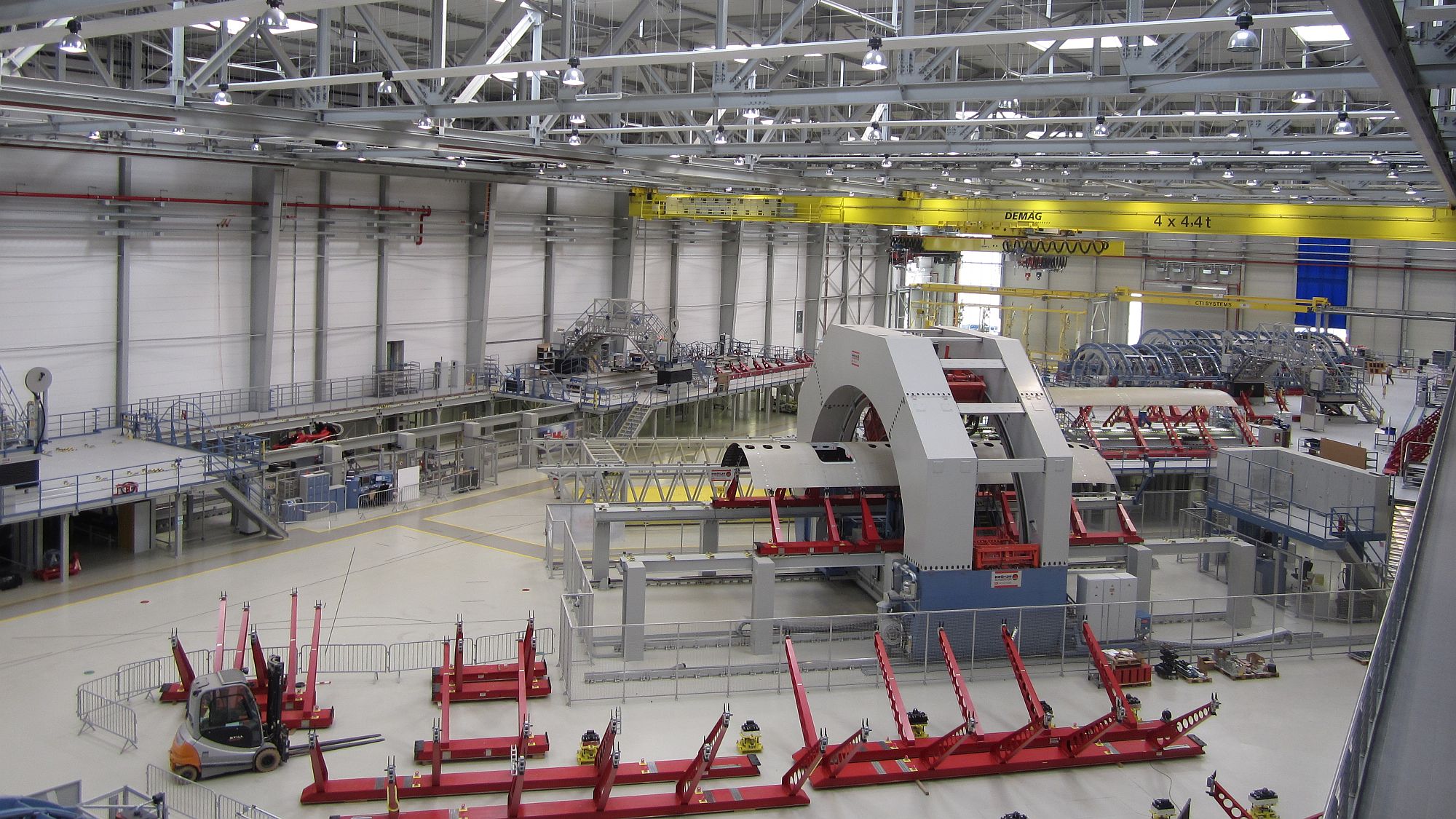

The complex aspects of the individual areas are comprehensively examined in order to put together the best possible concepts for our customers. The use of advanced technology for the factory of the future and efficient hall utilization are at the focus of our engineering concepts.

Analysis of relevant parameters for future planning

The very first step of each study work is to analyze any existing or planned production situation, parts to be manufactured, production rates, work force conditions and shop floor resources.

Define Key Characteristics, Process flow & Select Equipment

For large assemblies (e.g. aircraft parts) specialized procedures and knowledge is required. Our experts provide extensive knowledge about state-of-the-art technologies to be used for large scale assembly tasks.

Process Capacity Calculation & Simulation

Static and dynamic simulations give us a first view by summarizing processing times per station regarding manual and stationary workload.

We simulate your future facility including shift models, station bottlenecks, distribution of resources and error robustness. This allow to optimize your facility layout long before any hardware investment has to be made.

Selection of suitable technology for the current scenario

From first paper sketches to complete factory layouts in 3D, we create and evaluate tailor-made concepts.

Solutions are tested for commercial feasibility, maturity (production hardened) and harmony with production plant wide technology. This ensures to get the best deal for the customer.

VE2E: Research project for the development of the factory of the future a complete success

- Published on 11 March 2024

- Allgemein

- Assembly

- Digitalization

- Events

- Factory of the Future

- Service

It began as a promising vision in July 2021 and has now come to a successful conclusion: the research project “Vertically integrated, sustainable end-to-end factory (VE2E)” for the development of a digital Factory of the Future. At the beginning of March, the forward-looking results of the research project were presented to a wide audience at Premium AEROTEC’s Varel site.

Aircraft Production goes “GREEN” – Broetje-Automation Collaborates with Airbus Aerostructures to Promote Sustainable and Resource-Efficient Production

- Published on 23 February 2024

- Company

- Factory of the Future

- Service

Broetje-Automation has successfully collaborated with a broad industry consortium to identify ways to reduce the environmental impact of today’s production facilities. The “GREEN” project, a joint initiative of a consortium of partners including OFFIS e.V., DLR e.V., ProIng and Broetje-Automation GmbH under the leadership of AIRBUS Aerostructures, developed measures to reduce the power consumption of old systems by up to 85% in certain areas of application. Overall, especially retrofitting older systems allows significant contributions towards a more sustainable industrial production.